How do innovations affect the production of brushes?

2025-01-25

Innovations play a key role in the development and improvement of various industries. This also applies to the production of goods, such as brushes. Modern technological achievements allow manufacturers to create better, durable and effective products.Brush factory- This is not just a place where brushes are made, it is a whole ecosystem of innovation, continuous development and adaptation to market needs. Innovative approaches in production simplify processes, reduce costs and increase performance. Today, buyers expect not only high functionality, but also the environmental safety of products, which also pushes manufacturers to the development of new technologies. Let's look at how exactly innovations affect the production of brushes, affecting various aspects of this industry.

Improvement of materials

One of the main aspects of innovation in the production of brushes is to improve the materials used. Thanks to modern research achievements, new composite materials are born that have unique properties. These new materials make brushes more durable, flexible and functional. The emergence of technologies such as nanocomposites and polymer hybrids significantly expands the range of opportunities for manufacturers.

In addition, the materials safe for ecology are a mandatory requirement. The use of processed or biodegradable materials gives manufacturers the ability to offer products that are not only effective in use, but also minimally affects the environment.Brush factoryActively introduces such approaches, which makes their products more competitive.

Technological production

Modern production technologies, such as automation and robotization, significantly improve the quality of brushes. The introduction of robotic systems allows you to minimize the human factor and increase the accuracy of processes. The use of machines with numerical control (CNC) makes it possible to produce more complex shapes and designs of brushes, which were previously considered impossible.

Such technological progress allows you to accelerate production processes and make them more flexible.Brush factoryActively uses such systems to improve the performance and quality of its products. These technological changes create the conditions for creating brushes that perform their functions better and have a longer service life.

Aesthetic design

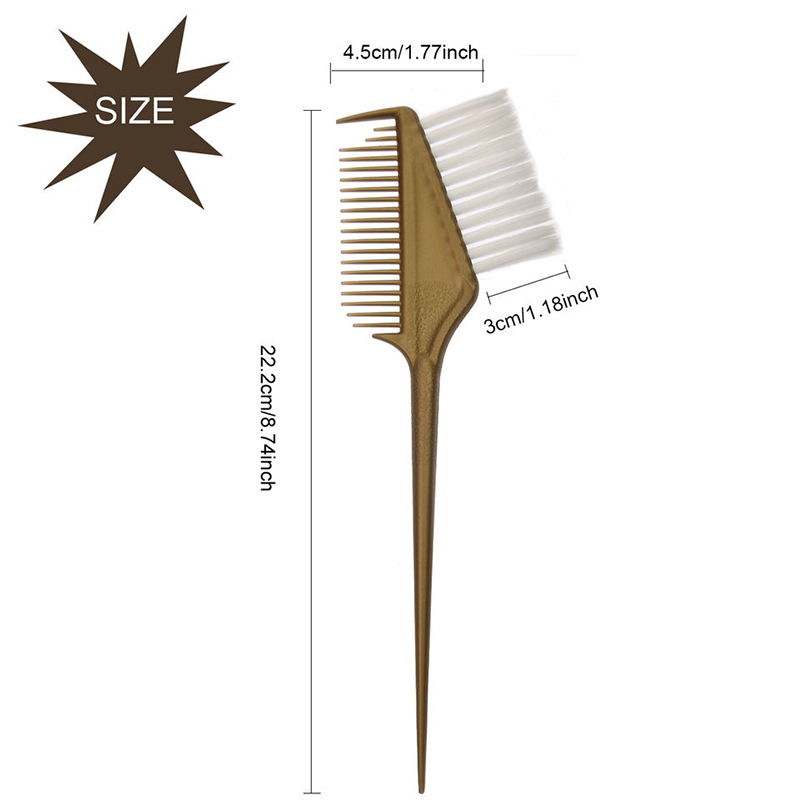

Innovation in the field of design allows you to create more attractive and ergonomic products. Modern design takes into account not only functionality, but also aesthetic type of product. The brushes became not only a cleaning tool, but also an element of style and image.

The use of 3D printing and quick prototyping technologies allows manufacturers to experiment with forms and create unique models of brushes that stand out on the market. Various colors, textures and forms allow you to satisfy even the most exquisite desires of customers, which increases their loyalty and interest in products.

Energy saving

Innovation in production is not limited only to improving the quality of products. The use of more effective production methods also helps to reduce energy consumption. Thanks to the introduction of energy -efficient technologies, the costs of processing materials and the production of brushes itself are reduced, which ultimately reduces the cost of products.

This aspect is especially important against the background of an increase in energy prices. Forcing enterprises to find ways to save resources, environmentally sustainable production becomes critical.Brush factoryIt develops models that take into account the consumption of resources at all stages of the production process and minimize it.

Innovation in the marketing and sales system

With the development of technology, approaches to doing business also change. Modern companies actively use digital tools for marketing and sales. Online platforms and social networks have become a powerful tool for promoting products, allowing you to achieve more customers and offer them personalized solutions.

The multi -channel sales approach makes products more affordable and increases sales. The use of Big Data analytics allows you to better understand customer needs and improve the product range. Marketing campaigns become more targeted and, therefore, more effective.

Environmental responsibility

Demand for environmentally friendly products continues to grow. Brush manufacturers are actively working on a decrease in an ecological trace, using materials and technology safe for the environment. This applies to both the products themselves and packaging. Attention to the issue of sustainable development becomes a prerequisite for working in the market.

Production, which takes into account the principles of environmental responsibility, receives not only a competitive advantage, but also contributes to improving the state of the environment. This is important for the formation of a positive image of the brand and attracting conscious consumers.

Arguing all these aspects, it becomes obvious thatBrush factoryIt is able to significantly raise its products to a higher level, providing customers with innovative solutions for everyday needs. Innovations not only improve products, but also change the principles of approach to production, making it more modern, effective and sustainable.